Shelf-Life Testing & Product Stability

How long can your product stay safe and of good quality? That question isn’t just about consumer satisfaction—it’s about regulatory compliance, profitability, and brand trust.

Whether you’re producing sauces, ready-to-eat meals, baked goods, or beverages, understanding and controlling shelf-life is critical. In this post, we will explore why shelf-life testing matters and what to consider beside a lab test programme.

What is Shelf-Life Testing?

Shelf-life testing determines how long a product remains safe, stable, and appealing under recommended storage conditions.

Key Outcomes of Testing

- Microbiological safety – Preventing spoilage and foodborne illness

- Sensory quality – Maintaining taste, colour, aroma, and texture

- Nutritional integrity – Ensuring key nutrients remain within specified levels

- Regulatory compliance – Meeting labelling and health authority requirements for example SFA, or HPB.

Why Shelf-Life Matters to F&B Businesses

A wrong or inaccurate shelf-life can lead to:

- Product recalls and legal penalties

- Loss of consumer trust due to early spoilage or poor quality

- Increased wastage and damaged profitability from short or unpredictable shelf life

With proper testing, you can:

- Optimise production and distribution timelines

- Reduce waste through accurate expiry dating

- Improve customer satisfaction and repeat business

Key Factors That Affect Shelf-Life

Several factors impact how long your product will remain stable:

- Ingredients – Especially perishable or high-moisture content items

- Processing method – Cooking, freezing, pasteurisation, or drying can extend life

- Packaging – Barrier protection against air, light, moisture, and microbes

- Storage conditions – Temperature, humidity, and handling during warehousing and transportation

Understanding these will help you design testing protocols suited to your product’s characteristics.

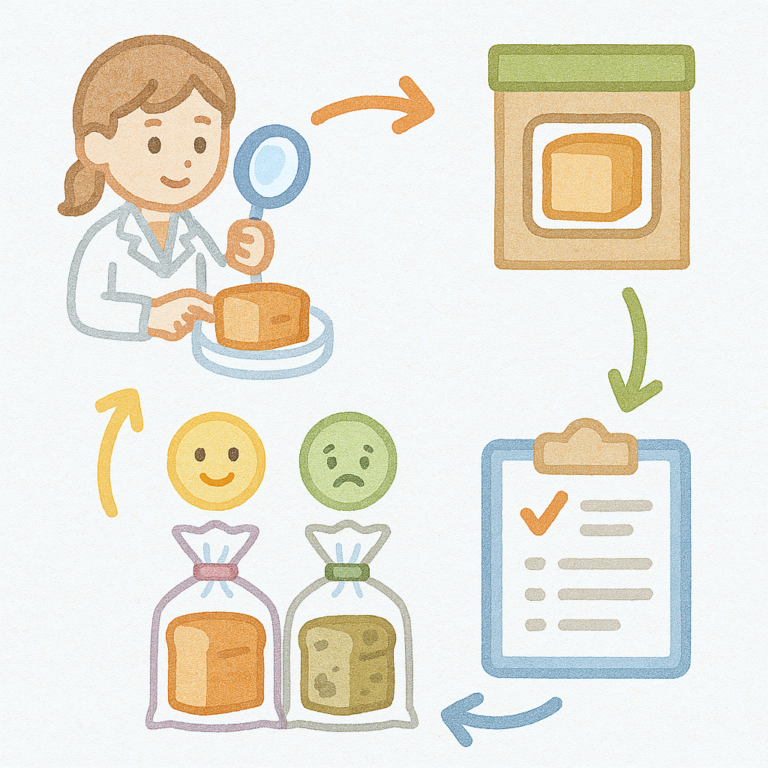

How to Conduct Shelf-Life Testing?

A shelf-life study should follow a structured process:

-

Step 1: Product Profiling – Define ingredients, expected hazards, and packaging

-

Step 2: Testing Design – Choose between real-time, accelerated, or predictive testing

-

Step 3: Microbial & Sensory Testing – Evaluate safety and consumer appeal over time

-

Step 4: Data Analysis & Expiry Decision – Establish expiry date and safe usage window

-

Step 5: Documentation & Review – Record results for audits and make updates after formulation or packaging changes

Work with food consultants and accredited labs to ensure accuracy and validity.

Ongoing Shelf-Life Monitoring

Shelf-life is not a “set-it-and-forget-it” situation.

It needs:

- Regular verification of labelled shelf life

- Ongoing testing and tasting

- Reevaluation when there’s a change in ingredients, packaging, or process

Investing in continuous monitoring helps keep your product safe, compliant, and competitive.

Final Thoughts on Shelf-Life Testing & Product Stability

Shelf-life testing is not just a technical process—it is a business-critical activity. Getting it right ensures product safety, protects your brand, and supports your long-term goals.

If you need help building a robust shelf-life validation programme, Food Forward is here to support you.

Get in touch with us today!