How central kitchens can maximise efficiency and profitability

What is a central kitchen and why use one?

More food businesses in Singapore and the region are turning to central kitchens to improve efficiency, control costs, and support business growth. But running a central kitchen well is not simple. Without the right processes, it can become a source of bottlenecks, food safety issues, and waste.

In this post, we look at practical considerations to design and manage a central kitchen for better performance and consistency.

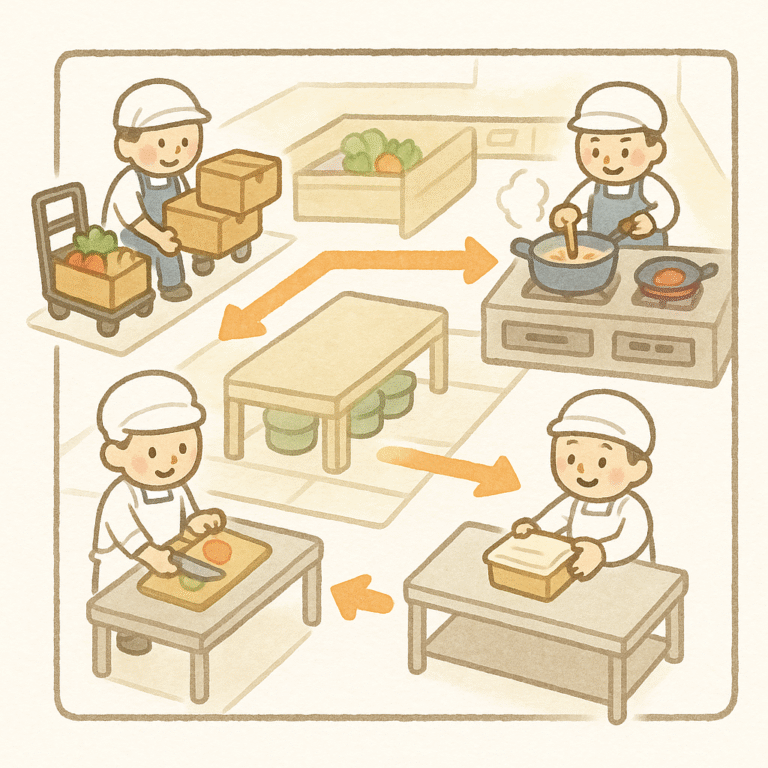

A central kitchen prepares and processes food for multiple outlets or sales channels.

Common benefits include:

✔ Standardised quality across outlets

✔ Improved control over food safety

✔ Bulk buying and production cost savings

✔ Efficient use of labour and equipment

✔ Support for new channels (e.g. delivery brands, B2B sales)

A well-run central kitchen gives your business a stronger operational backbone and supports scaling up.

The layout and process flow of a central kitchen have a big impact on performance.

Optimise these areas to drive efficiency:

✔ Space planning: Clear flow from goods-in to goods-out

✔ Zoning: Separate raw and cooked zones to prevent cross-contamination

✔ Equipment placement: Based on process sequence, not convenience

✔ Batch production: Scale prep for consistent quality and reduced cost

A central kitchen can deliver cost savings, but only if labour is well managed.

Key labour and cost management practices:

✔ Cross-train staff to handle multiple tasks

✔ Use visual work instructions and portioning tools

✔ Implement lean techniques to cut wasted motion and time

✔ Track labour cost per kilo/unit produced

Align food safety, consistency, and scalability. Food safety must be designed in from day one.

Important areas to manage:

✔ Temperature control through every stage

✔ Allergen segregation

✔ Hygiene zoning and staff movement patterns

✔ Cleaning verification and record keeping

As you scale, revisit processes to ensure they still meet food safety requirements and production targets.

Even experienced food businesses sometimes run into central kitchen problems.

Watch out for these common pitfalls:

✔ Designing a facility too small to support future growth

✔ Failing to review and update workflows as the business scales

✔ Letting complexity creep in by trying to overstretch the capabilities

✔ Ignoring the need for proper training and onboarding

A central kitchen is a dynamic environment. Processes must evolve as the business grows.

Final thoughts.

Need expert guidance on central kitchen design or process improvement?

A central kitchen is not just a production space. It drives business performance. Good design, smart processes, and strong food safety practices help ensure that your kitchen supports your goals, instead of slowing you down.

Food Forward can help.

Get in touch with us today!